Description

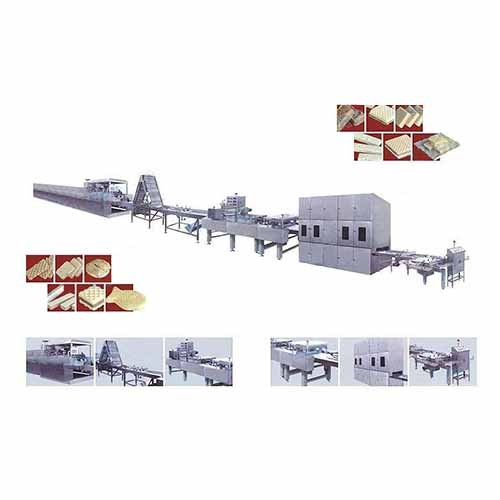

Fullly-Automatic Wafer Production Line

Feature:

Adopting advanced technology with elctric

and gas as heating source,this full-auto wafer production line is a new

generation product developed exclusively in China based on the advanced

structure of existing plants from domestic market and abroad.If offers an ideal

solution for lower power consumption and overall production cost,and

keeping the same surface color for all biscuits.The plant mainly consists of

mixing system,automoatic feeding system, tunnel-type oven, sheet feeding and

cooling device,cream coating machine,cutter and organic heating medium boiler,

ect.With compact structure and unique reliability, the plant is one of the most

preferred equipments in foodstuff industry.

Technical parameters:

1.Blender Mixer

The machine is the mixing system, the first

technology processing equipment in wafer manufacturing. It adopts the separate

delivery and automatic circulation system.

Material: the machine frame is made of

steel with international standard and the cover adopts imported 304 stainless

steel plate with thickness of 1.2mm

Twin mixing barrels made of imported 304

stainless steel plate with thickness of 3mm, Mixture pump (Guangzhou)

Electrical appliance switch (Schneider of

Germany), Electrical machine (SEW of Germany)

Main technical parameters:

Mixture quantity per time: 60kg/flour 25kg

Power consumption: main electrical machine

380V 3KW 2900r/min

Model: Y100L2-4-V1

Mixture pump electrical machine: 380V

0.75kw

2.Cream Mixer

The machine mixes the sugar, butter and other

matters abundantly according to the technology prescription.

Materials: the machine frame is made of

steel with international standard and the cover adopts imported 304 stainless

steel plate with thickness

Cream barrel adopts imported 304 stainless

steel plate with thickness of 3mm

Electrical machine (SEW of Germany),

Decelerating machine (SEW of Germany)

Main technical parameters

Drive electrical machine for cream

spreading roller: JWB-×0.75-40DII

Drive electrical machine for convey belt

and wafer block pressing roller: JWB-×0.75-40DII

Drive electrical machine for to-and-fro

laminating machinery: Y802-4 0.75KW

Power of thermoelectric tube for cream

spreading roller and cream mixing roller:220V 0.3KW×2

3.Mainframe Oven

As the most important equipment of

full-automatic wafer production line, tunnel gas baking machine has

extraordinarily outstanding performances with the main characters as follows:

1. Unanimous heat colors of wafer block.

Thanks to the scientific selection of heating components, superior material

selection for baking plate and reasonable die carrier structure, the heat

colors of the center and periphery of the wafer block having been baked are

unanimous.

2.High rate of certified products with

finished product rate of not less than 98%. Because of uniform heating and

unanimous heat colors, the demoulding rate of biscuit is high with improving

rate of certified products accordingly.

3.Small cubage. As a result of reasonable

layout, the body length of the baking oven is only 2/3 of the same type of

product, which saves space greatly.

Quantity of template: 27 model

Size of template:470mm×325mm

Adjusting range of wafer block thickness:

2.5mm-3.2mm

Demoulding method: automatic demoulding。

Adjusting range of temperature: normal

temperature to 180℃

Temperature error:1℃

External dimensions (L×W×H):

8500*1560*2400mm

4.wafer sheet cooling machine

The machine runs slowly to cool down and

convey the wafer block.

Materials: The machine frame is made of

steel with international standard and the cover adopts imported 304 stainless

steel plate with thickness of 1.2mm and Φ6 stainless raw material.

The machine runs slowly to cool down and

convey the wafer block

weight:100kg

size:2540*500*1300mm

5.Cream spreading machine

The cream is applied, laid up and laminated

automatically and regularly before the wafer block is sent to the conveying

belt.

1.Frame: Material with international

standard

2.The cover adopts imported stainless steel

plate

3.Convey belt: Italy

4.Continuously variable transmission:

Germany SEW

5.Converter :Japan's Mitsubishi

6.Process controller:Siemens of Germany

7.Photoelectric switch :German Schneider

Main technical parameters

Drive electrical machine for cream

spreading roller: JWB-×0.75-40DII

Drive electrical machine for convey belt

and wafer block pressing roller: JWB-×0.75-40DII

Drive electrical machine for to-and-fro

laminating machinery: Y802-4 0.75KW

Power of thermoelectric tube for cream

spreading roller and cream mixing roller:220V 0.3KW×2

6.Wafer cutting machine

The machine is equipped with to-and-fro

conveying belt and it can cut the wafer block to all sizes.

Materials: the machine frame is made of

steel with international standard and the cover adopts imported stainless steel

plate

Procedures controller (Siemens of Germany)

Proximity switch German Schneider

Electrical machine (German SEW), Electrical

machine power: 380 0.75W N=1400r/min

Decelerating machine type: I=24:1

a.The largest cutting height 55mm

b.Cutting the minimum height

c.Cutting Size : Each cutting machine of

the two specifications, the other may choose

d.Cutting by Steel wire ,the Line diameter

of the steel wire:

0.3mm and 0.5mm can be Optional

e.Dimensions: (L×W×H): 0.9m×0.62m×0.82m

Weight :about 600kg Electricity Power: 750W

7.Swashing Machine(waste recycling)

This machine is a kind of supplementary

equipment and utilized for waste recycling.

Material: the machine frame is made of

steel with international standard, and adopts imported 304 stainless steel

plate with thickness of 3mm

Electrical machine (SEW of Germany)

Electrical machine power: 380V, Y112-4,

4kW, 50H2

weight:150kg

size:690*610*880mm