What is the difference between “pre-stretch” and “Resist-stretch” of the stretch packaging machine?

Resist stretch wrap film and pre-stretch wrap film are two different types of wrap film, which have significant differences in material, production process and usage effect. Correspondingly, the working principle and equipment characteristics of stretch film machine and pre-stretch film machine are also different. The following is a detailed comparative analysis of these two types of film and their machines.I. Difference between stretch film and pre-stretch film

1. Material and production process

Resist stretch film is usually wound without stretching, which has no specific requirements on the material of the film and can realize the winding process by adjusting the friction damping of the resist stretch mechanism. This type of film can provide sufficient protection at a low cost and is widely used for packaging a variety of items.

Pre-stretch wrap film, on the other hand, is wound under the stretch of a given size mold, which requires the film to have good tensile properties and resilience. By pre-stretching, this kind of film can improve the tightness and aesthetics of the package, which is suitable for the scenarios with high requirements on the packaging effect.

2. Use effect

Since the stretch-resistant wrap-around film is not pre-stretched, its wrapping effect may be relatively loose, but it is sufficient for the packaging of general articles. In addition, the cost is relatively low because the material requirement of the film is not strict.

Pre-stretch wrapping film, after stretching treatment, can better fit the shape of the items and provide stronger fastening force and stability. At the same time, due to its better stretching performance and resilience, it can effectively prevent the items from being shifted or damaged during transportation. Therefore, pre-stretch wrapping film is usually used in scenarios that require higher packaging effect.

Difference between stretch wrapping film machine and pre-stretch wrapping film machine

1. Working Principle

Stretch wrapping film machine controls the stretching speed of the film by adjusting the friction damping of the stretching mechanism, so that the speed of the film when it is pulled out passively is slower than the speed of the rotation of the palletized goods, thus forming a tight wrapping layer on the goods. This kind of machine is suitable for the scenarios that have certain requirements on cost and do not have high requirements on packaging effect.

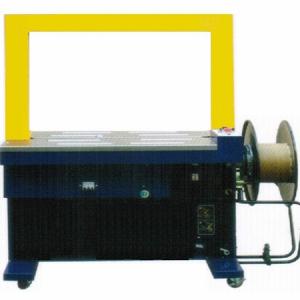

The pre-stretch wrapping machine uses a powered pre-stretch frame mechanism to stretch the wrapping film to a pre-set “stretch ratio” and then wrap it around the palletized goods. This type of machine can provide higher tightness and aesthetics, and is suitable for scenarios that require higher packaging effect.

2. Equipment Characteristics

The structure of stretch wrapping film machine is relatively simple and low cost, and there is no strict requirement on the material of film. This makes the stretch wrapping machine widely used in various industries and also reduces the cost.

Prestretch winding film machine, on the other hand, has higher technical requirements and precision requirements, so its cost is relatively high. However, they are widely used in some specific industries because of their ability to provide high quality packaging results and greater stability.

To summarize, stretch resistant film and pre-stretch film are different in production process and usage effect; accordingly, there are differences in working principle and equipment characteristics between stretch resistant film machine and pre-stretch film machine. Users should select the right type of film and machine according to their actual needs.